CUT produces a variety of different products for food filtration at its site in Erkrath near Düsseldorf: micro- and ultrafiltration membranes and modules. We are particularly interested in process engineering solutions that are tailored to your individual needs and optimized.

CUT filtration modules – manufactured in Germany, in use worldwide.

Robust and long-term stable T-CUT Core tube modules

As a module form for juice clarification, the T-CUT Core tubular modules have proved very successful. The large free flow cross-sections make them ideally suited for the filtration of liquids with high solids contents. The pore sizes of our ultrafiltration membranes are individually adapted to the separation task: Solids, colloids and microorganisms are retained, while the valuable ingredients of the juice, its colorants and aromas remain unchanged in the filtrate.

The concentration of trub substances can lead to the formation of a cover layer on the membrane during filtration, which can block the pores and impede the filtrate flow.

Our membrane polymers counteract the accumulation of substances so that they can be easily removed.

Here you can find more advantages of the T-CUT Core Tubular modules.

- high solids content possible

- high filtrate performance

- light rinsing/cleaning

- smooth surfaces

- Extremely high mechanical stability

- food compliant

- Simple installation

- „Made in Germany”

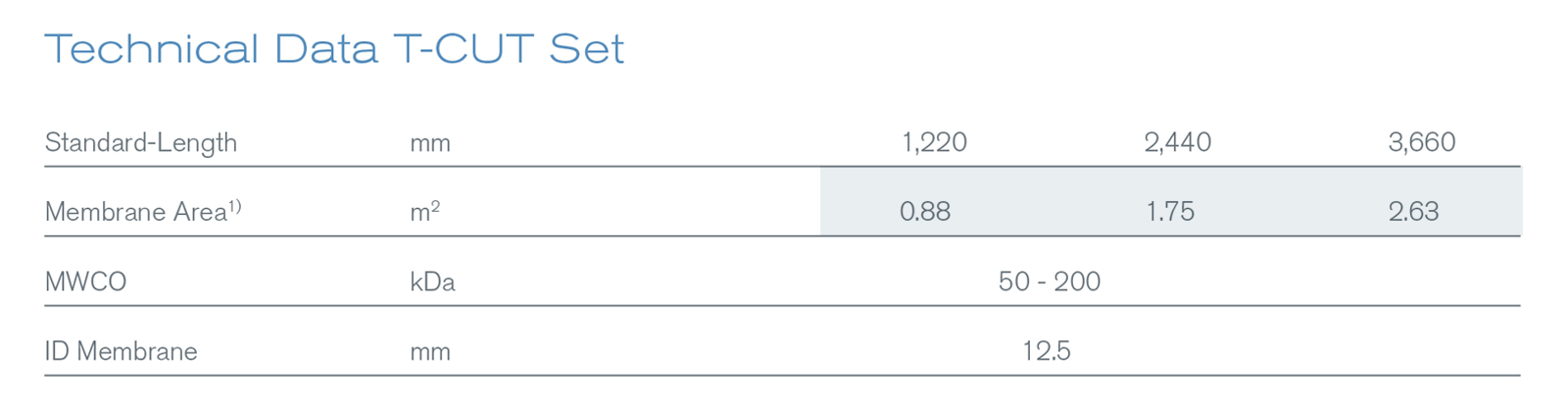

An innovative and cost-effective solution – the T-CUT Set

CUT Membrane Technology has expanded its product range with a new replacement membrane set. The T-CUT set, consisting of individual membrane tubes and the corresponding seals, enables cost-effective replacement of your modules.

A standard T-CUT set consists of 18 tubular membranes and 36 associated seals and is ideal for cost-effective re-equipping of commercially available modules. Other common set sizes with different diaphragm lengths as well as special sizes are available on request.

We will be happy to discuss these with you individually.

The T-CUT set is offered in three standard lengths: 1,220mm, 2,440mm and 3,660mm.

The individual membrane tubes consist of a highly stable nonwoven support fabric with a membrane layer made of PES or PVDF. They are robust and long-term stable against the chemical cleaning agents and temperatures commonly used in the food industry and deliver a permanently high filtrate performance and a consistently high filtrate quality.

C-CUT Capillary modules for wine filtration

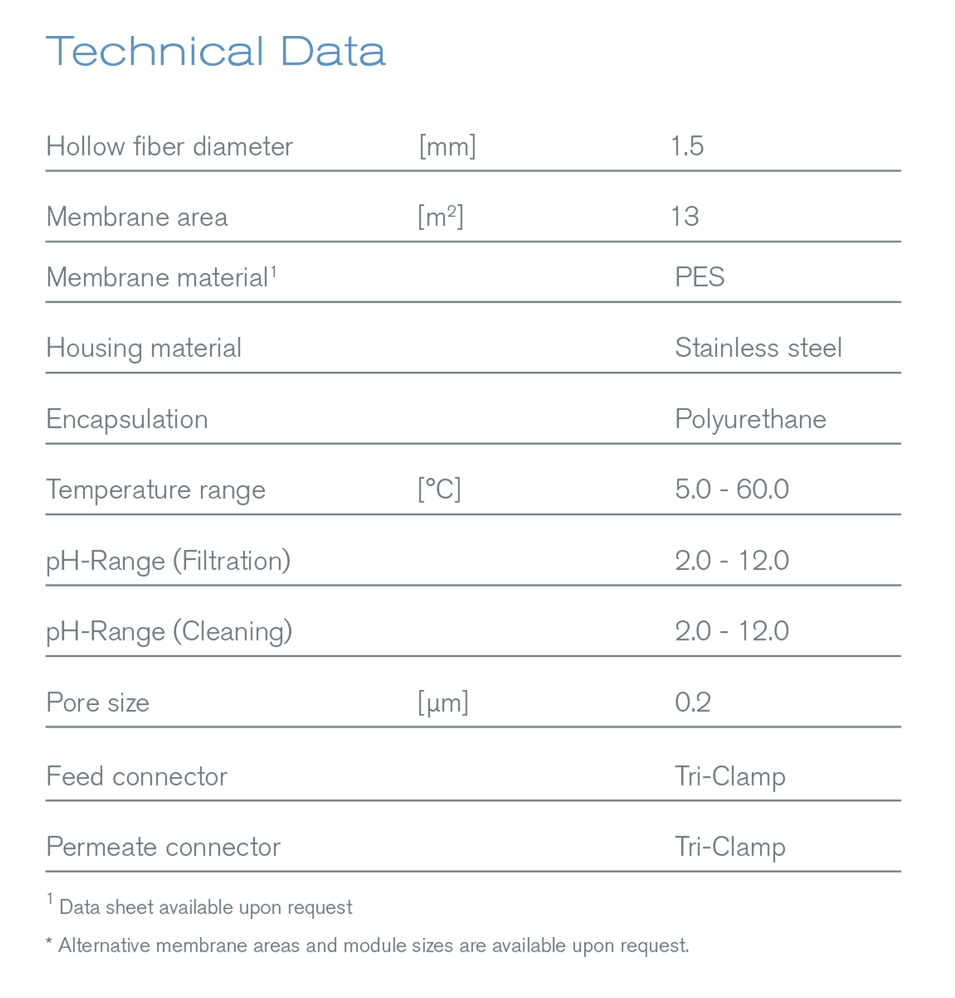

With the C-CUT capillary module, a high-quality microfiltration module has been developed especially for wine filtration.

The hollow fiber modules from the C-CUT series ensure high filtrate performance and safe use in the application.

Due to the high chemical, mechanical and thermal resistance, it is possible to clean and backwash the modules both chemically and mechanically. The necessary food testing (FDA) supports quality assurance in your filtration process.

More cost effective alternative

Advantages of the new C-CUT Core concept

- exchangeable module inserts (cores) for different applications

- No filter aids required

- simple and safe operation

- the greatest possible preservation of the sensory characteristics of the wine through the selection of high quality components

- Consistent filtration quality

- reliable filtration performance

- Low residual quantities due to high concentration

- Low space requirement and high service life

- highest safety in filtration

- exceptionally high filtrate performance leads to very short residence times of the wine in the module with low energy requirements and cleaning effort

- Global availability