CUT produces a variety of different micro- and ultrafiltration membranes and modules at its site in Erkrath near Düsseldorf.

We are particularly interested in process engineering solutions that are tailored to your individual needs and optimized.

CUT filtration modules – manufactured in Germany, in use worldwide.

Tubular Modules for Ultrafiltration

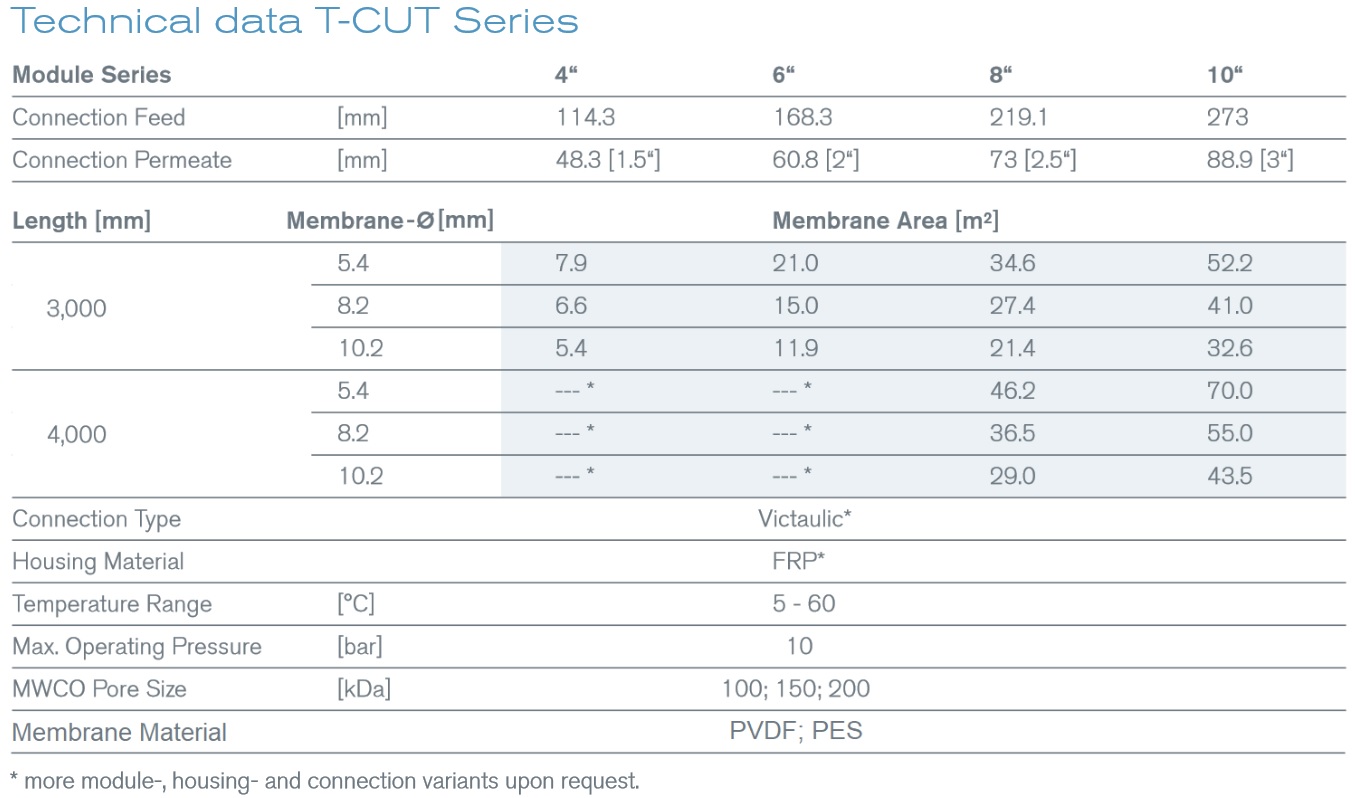

CUT Membrane Technology offers robust tube modules with different exclusion limits with its T-CUT UF series. The diaphragms are applied to very high-quality support material and are characterized in particular by a long service life and long durability.

Due to the high stability of the membranes and the possibility of chemical cleaning, T-CUT tube modules can also be used in applications with extreme requirements.

For example, our T-CUT UF pipe module series in GRP construction has successfully proven itself for years worldwide as the “standard product” of choice when it comes to the separation / concentration of biomass in a landfill leachate application.

Tubular Module Replacement Solution

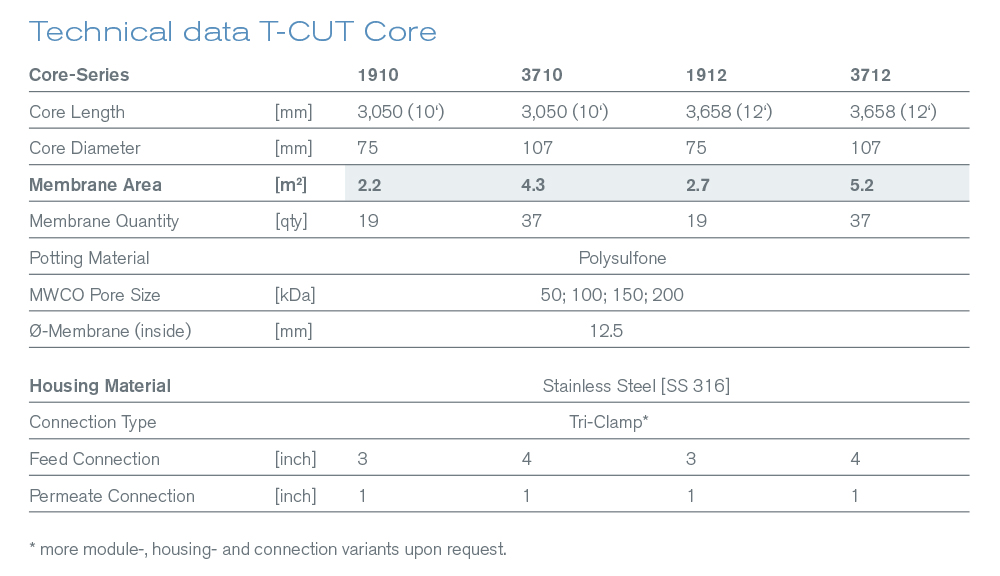

CUT Membrane Technology enables a significant reduction in membrane replacement costs with the Core concept.For original equipment, a robust stainless steel pressure housing is combined with our replaceable T-CUT Core membrane filtration elements. If the membrane needs to be replaced after years, the housing remains in the filtration system for further use; only the membrane core is replaced. At the same time, the membrane exchange is user-friendly and can be implemented in practice with little effort.

The Core concept combines the advantages of our proven T-CUT UF pipe module series in terms of durability and reliability with tangible economic and ecological benefits. The open flow cross-sections are particularly suitable for the filtration of media with very high solids contents and industrial wastewater.